Featured Products

Recent Blogs

Elevating Your Golf Game: Unveiling Mitchell Golf – The Gold Standard in Loft and Lie Machines.

August 15, 2023

Mitchell Machines #1 On Tour Worldwide – Club Repair Supplies & Tools

Build Shop Hacks/Tricks

July 20, 2023

Mitchell Machines #1 On Tour Worldwide – Club Repair Supplies & Tools

Getting Club Ready for the Upcoming Season

May 8, 2023

Mitchell Machines #1 On Tour Worldwide – Club Repair Supplies & Tools

About Us

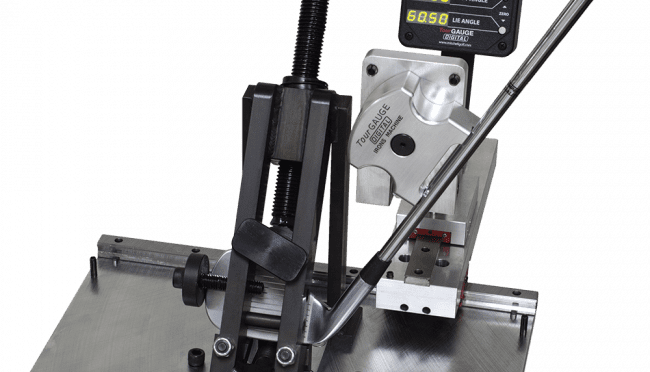

Mitchell® Golf Equipment Company started in 1988 manufacturing the Steelclub® Angle Machine. The company has revolutionized custom club fitting and club making in the golf industry by accurately measuring and bending cast & forged irons, metal woods, hybrids, and putters.

Today, Mitchell Golf Equipment manufactures a complete line of proprietary designed club repair tools, including the golf industry’s professional-grade measuring and bending angle machines under the brand names of Steelclub and TourGauge. These machines are found in repair vans on all PGA & LPGA tours worldwide for more than 30 consecutive years.

Mitchell® Golf has made a lot of friends over the years with customers in every country that enjoys the game of golf. We thank everyone for their past and continued support. Customer service is Mitchell® Golf’s number one product. Our employees are proud of the many “Made In USA” products we manufacture for the golf industry and we welcome your business. Mitchell® Golf Equipment Company is located at 1001 Industrial Blvd, Albion, MI, 49224.