Using Frequency to Produce a Matched Set of Golf Shafts.

We use frequency to measure the flex of the shaft in a club. This absolute measurement produces a “matched set of clubs” of the same flex feel.

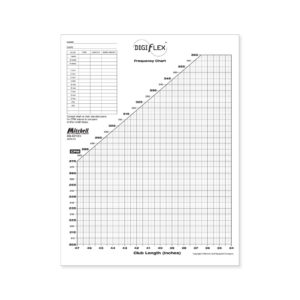

This is made possible by measuring and comparing each shaft’s frequency in a set of clubs to the desired gradient on a chart. The gradient can vary with different shaft designs and geometry.

Shaft flex: Do ya feel me?

All shaft manufacturers design their shafts to produce certain ball flight results and a specific “flex feel.” Typically, shaft manufacturers label their shafts’ flex designation with a letter L-A-R-S-X or a word like FIRM, SOFT, or STIFF.

The problem for golfers is that one manufacturer’s flex designation can differ from another’s. Frequency can be used to compare these other designations for the actual “feel” best suited for individual golfers.

The frequency of golf shafts is measured in “cycles per minute,” commonly referred to as CPM. To obtain this measurement, place the grip end of a golf club into the clamp of your Mitchell Golf DigiFlex Meter. This clamp will provide constant pressure on the shaft.

Next, line the laser over the edge of the shaft. Flick your shaft to make it oscillate. The lower end of the scale will be a shaft that flexes a lot, while the higher end would be a very stiff club. The rate of frequency (CPM) does not depend on the force required to create the oscillation.

The advantage of a frequency-matched set of clubs allows a golfer to swing each club in their bag with the same tempo to achieve maximum clubhead velocity at impact for ideal ball flight.

The advantage of a frequency-matched set of clubs allows a golfer to swing each club in their bag with the same tempo to achieve maximum clubhead velocity at impact for ideal ball flight.

Frequency is also used to match a shaft when replacing a broken shaft. It determines the flex of a golfer’s favorite club for building other clubs with similar shafts.

It can be used to measure the symmetry of a shaft by comparing the CPM reading around the shaft’s circumference in 6 equal 30° planes. When the CPM varies 3 cycles or less, the shaft is considered to be symmetrical.

Mitchell Golf’s DigiFlex 2.0 Frequency Meter.

The machine used to measure frequency is a Frequency Meter offered by Mitchell Golf as the DigiFlex 2.0 Frequency Meter. First introduced in 1994, the DigiFlex Frequency Meter has set the standard in the golf industry for accuracy and reliability.

Highlights:

- DigiFlex 2.0 uses a laser beam to measure CPMs in .01 increments accurately. Using a laser influences from outside light sources are eliminated, and response time is vastly improved.

- DigiFlex 2.0 measures frequency horizontally, which reduces the effects of mass at the end of the shaft

- DigiFlex 2.0 Frequency Meter reads and displays values from .5 CPM to 30,000 CPM. The display is customized to the customer’s personal or business name.

- It is powered by a Lithium battery for hours of operation and can be charged and powered from any standard USB port.

The DigiFlex system utilizes a constant pressure clamping vise that has been a hallmark for the accuracy of the DigiFlex Frequency Meter for years. The clamping vise comes with an interchangeable shaft clamp and a tapered-contoured grip clamp for measuring the frequency of raw shafts or gripped clubs regardless of the grip durometer or size.

A unique feature of the Digiflex is that the measuring and display box is mounted to a bearing plate attached to a precision ground slide rail. This ensures the proper positioning of the meter to accommodate different club lengths from 30” to 48”.

It’s also the only system that measures the shaft frequency in a horizontal plane, thus removing the influence of gravity. This feature produces accurate and consistent readings. Systems that use vertical oscillation are influenced by the effects of gravity to a greater degree and are not entirely correct due to inconsistencies.

The DigiFlex 2.0 Frequency Meter uses state-of-the-art updatable firmware, making it future-proof. Add this state-of-the-art frequency system to your club building and repair business, or upgrade your old DigiFlex Frequency Meter today.

The advantage of a frequency-matched set of clubs allows a golfer to swing each club in their bag with the same tempo to achieve maximum clubhead velocity at impact for ideal ball flight.

The advantage of a frequency-matched set of clubs allows a golfer to swing each club in their bag with the same tempo to achieve maximum clubhead velocity at impact for ideal ball flight.