Spending money on a new set of clubs isn’t hard to do in golf, but determining club flex and the frequency of your club’s shaft is. Frequency is used to produce a “matched set of clubs” to give the set the same flex feel. This allows a golfer to swing each club in their bag with the same tempo. The goal is to achieve maximum clubhead velocity at impact for ideal ball flight.

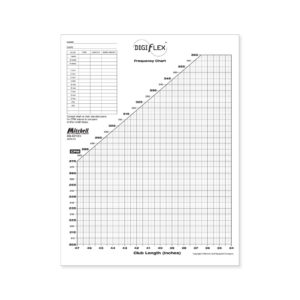

Understanding the true flex of clubs is made possible by measuring and comparing each shaft’s frequency in a set of clubs to the desired gradient on a chart. The gradient can vary with different shaft designs and geometry. That’s why it is important to know how the shaft’s geometry relates to a golfer’s “feel”.

All shaft manufacturers design their shafts to produce certain ball flight results and to a specific “flex feel”. Typically, shaft manufacturers label their shafts’ flex designation with a letter L-A-R-S-X or a word like FIRM, SOFT of STIFF. The frequency of golf shafts is measured in Cycles Per Minute (CPM). The higher the CPM, the stiffer the shaft.

However, there is no clear standard of shaft stiffness in the industry. The typical result is that most club’s flex designations don’t play to the specs represented on the label. Frequency can be used to compare these different designations for the actual “feel” best suited for individual golfers. How important is getting the right feel? One customer who recently ordered a Digital Frequency Meter went on to win a major PGA championship.

Frequency is also used to match a shaft when replacing a broken shaft. It is used to determine the flex of a golfer’s favorite club for building other clubs with similar shafts. It can also be used to measure the symmetry of a shaft. This is accomplished by comparing the CPM reading around the shaft’s circumference in 6 equal 30° planes. When the CPM varies 3 cycles or less, the shaft is considered symmetrical.

The best way to determine club flex and the frequency of a set of clubs is by using The Mitchell Golf DigiFlex 2.0 Frequency Meter. The Frequency Meter makes multiple measurements and averages these measurements over a defined period of time. This is done to calculate frequency and ensure accuracy and reliability. Our machine also uses the horizontal method of measurement rather than the vertical method used by most competitor systems. By measuring horizontally, the DigiFlex 2.0 greatly reduces the effects of mass at the end of the shaft.

We’ve made this point often, but it is one that is worth repeating: There is no flex standard in the golf industry today. Frequency provides an absolute way to measure the stiffness of a shaft. Once this is determined, shafts can then be matched to a player’s swing to improve performance. And better performance always makes the game more enjoyable.