An Industry Professional’s Guide To Angle Adjustments

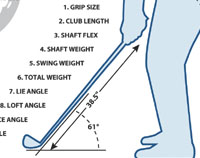

Using a club bending machine to change the angle on a golf club is among the fastest ways to improve a player’s ball flight. Whether changing the lie to enhance accuracy or the loft to ensure that the player’s clubs are progressively consistent, angle bending is a major factor in club performance.

Even with the knowledge of club bending and its importance on your play, there are a lot of misconceptions about what can and can’t be done with a club’s loft and lie. Can you bend a metal wood? Are there ways to ensure a club won’t break? How accurate are clubs’ loft and lie readings straight from the manufacturer?

Here are some of the facts and fallacies about club adjustment.

1. A manufacturer’s new set of clubs doesn’t guarantee accuracy.

While golf club manufacturers try to make a consistent product, there are often inconsistencies in the lofts and lies of the clubs, and they may not be progressively consistent from one club to another.

• Clubs are mass-produced with certain manufacturing variances in every factory. Remember, the set is not necessarily progressively consistent from one club to another; therefore, each club should be checked.

• You can easily bend the lofts and lies to be progressively consistent from one club to the next with zero tolerance. You can also bend the angles to a consistent specification that is precisely fit for any golfer.

Check out our video: how-to bend your clubs on a Mitchell Golf Angle Machine:

2. All bending machines are not accurate in their readings

Machines with fixed measuring gauges will not be accurate when measuring clubs with offset, progressive offset, or face progression hosel positions. Machines that adjust for all hosel positions, such as Mitchell® Angle Machines are accurate regardless of the offset or hosel design of the golf club.

| |

3. A properly manufactured club can be bent many times without breaking

Even the most skilled repair professionals can occasionally break a club. When this happens, it’s usually the result of some inconsistency in the club’s metallurgy.

Even the most skilled repair professionals can occasionally break a club. When this happens, it’s usually the result of some inconsistency in the club’s metallurgy.

• There is no worry about bending a club bent last year or last week. It can be re-bent without any adverse effect on it.

• In addition, once a club is bent to a given specification, it will stay there until changed by an outside force of either bending again or striking a hard object. Loft and lie changes are more or less permanent.

4. You can bend a club more than 2 degrees.

The 2-degree limit is only recommended when changing the lofts on irons due to the potential effect such bends will have on the sole angle of the club. If the hosel design and manufacturing processes allow it, the lie of iron can be bent 3-4 degrees or more with no compromise to the integrity of the head. This is especially true of clubs made with long hosels.

5. You can bend metal wood (with limitations).

Despite limitations, many of today’s metal woods are bendable, especially stainless-steel heads. Forged titanium models are bendable as well due to their softer titanium structure. Provided the hosel of the wood is long enough to allow the bending bar to fit over its length, metal wood can be bent to custom-fit a player. This applies to both face angle and lie.

Bending the loft is another story. Bending the hosel toward or away from the face plane opens or closes the club’s face angle. This will change the ball’s trajectory and can potentially cause misdirected shots.

Looking for hands-on training to repair, build, and alter clubs? Then be sure to check out our class offerings at the Mitchell Golf Performance School.

Still have questions? Please contact Patrick Gallagher at 800-437-1314 or email patrick@mitchellgolf.com.

He’s happy to answer any of your questions!